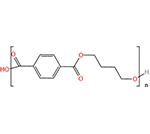

PBS (polybutylene succinate); Also known as polybutylene succinate, it is a biodegradable plastic made by the condensation of BDO and succinic acid. It belongs to the aliphatic polyester class and is easily decomposed and metabolized by various microorganisms or enzymes in animals and plants in nature, ultimately decomposing into carbon dioxide and water. The resin is milky white in color, with excellent mechanical properties and good heat resistance. Its thermal deformation temperature is close to 100 ° C, and the modified product temperature can exceed 100 ° C. It has good biocompatibility and biological absorbency, and is a typical fully biodegradable polymer material. The processing performance of PBS is currently the best among biodegradable plastics, and it can almost be used for various molding processes in existing general plastic processing equipment. At the same time, a large amount of inexpensive fillers such as PLA, calcium carbonate, starch, etc. can be blended with PBS to reduce costs.

application area

Mainly used in injection molding, packaging (including food packaging, cosmetic bottles, drug bottles), tableware, disposable medical supplies, agricultural films, pesticide and fertilizer slow-release materials, biomedical polymer materials and other fields.

| Item | Unit | Typical Value |

| Density(25℃) | g/cm³ | 1.25 |

| Melting point | ℃ | 110~116 |

| Melt flow rate | g/10min | 3-30 |

| Moisture content | % | ≤0.05 |

| Color L Value | – | ≥75 |

| Color A Value | – | ≤5 |

| Color B Value | – | ≤11 |

| Carboxy End Groups | MOL/T | 12-30 |

| Tensile Strength | Mpa | 32-55 |

| Break elongation | % | 260-600 |

| Flexural Strength | Mpa | 25-45 |

| Flexural Modulus | Mpa | 450-600 |

| Izod Impact Strength | KJ/㎡ | 5-15 |

More information, please contact with:

Li Huimin,Tel: 0576-85580185 ,Phone: 18825832103, Email:lhm@realsunchem.com

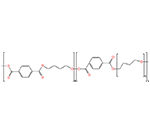

PBAT belongs to thermoplastic biodegradable plastics, which are copolymers of butyl adipate and butyl terephthalate. It has good ductility and elongation at break, as well as good heat resistance and impact resistance; In addition, it also has excellent biodegradability and is a fully biodegradable plastic. It is one of the most popular and best biodegradable materials in the research and market application of biodegradable plastics.

Mainly used in the production of plastic bags, food packaging, agricultural films, waterproof coatings for textiles, hygiene products (such as diapers), and personal protective equipment (such as gloves and respiratory masks).

More information, please contact with:

Li Huimin,Tel: 0576-85580185 ,Phone: 18825832103, Email:lhm@realsunchem.com

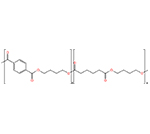

Thermoplastic polyester elastomer (TPEE) is an (AB)n-type block copolymer containing polyester hard segments and polyether soft segments. TPEE exhibits outstanding strength and heat resistance, along with excellent physical and chemical properties, making it a high-performance engineering plastic elastomer.

I. Structural Characteristics of TPEE

TPEE is a block copolymer (AB) composed of high-melting-point, high-hardness crystalline short-chain polyester hard segments (such as PBT) and amorphous long-chain polyether (such as polyethylene glycol ether, polypropylene glycol ether, polybutylene glycol ether) or polyester (such as polycaprolactone and other aliphatic polyesters) soft segments. Its structural formula is shown in the figure on the right.

The crystalline polyester hard segments aggregate into microcrystalline domains, dispersed in a continuous phase formed by soft-segment polyether or polyester. The crystalline phase acts as a physicalcross-linking agent. Upon heating, the microcrystalline domains are disrupted, allowing melt flow, and upon cooling, they re-form, demonstrating reversibility. The microphase-separated structure of TPU. The crystalline hard segments provide strength and plasticity, while the amorphous soft segments impart elasticity. Adjusting the relative proportions of the two phases can modify the polymer’s hardness, elasticity, melting point, chemical resistance, and gas impermeability. Increasing the hard-segment ratio enhances hardness, modulus, strength, heat resistance, and oil resistance,whereas increasing the soft-segment ratio improves elasticity and low-temperature flexibility but reduces heat resistance, oil resistance, and mechanical strength. The type, length, and content of both hard and soft segments influence TPEE’s properties.

II. Properties of TPEE

(1) Mechanical Properties

TPEE is an engineering elastomer with exceptional comprehensive performance, featuring high strength, excellent resilience, and outstanding resistance to creep, impact, flex fatigue, and abrasion.Its mechanical properties are closely related to its composition: as the hard-segment content increases, hardness, density, melting point, softening point, flexural modulus, and tensile strength increase, while elongation at break and resilience decrease accordingly. By adjusting the hard-to-soft segment ratio, TPEE’s hardness can range from 27 to 80 (Shore D), with elasticity and strength intermediate between rubber and plastic. Compared to other thermoplastic elastomers (TPE), TPEE exhibits a higher modulus under low-strain conditions for the same hardness. When modulus is a critical design factor, TPEE allows for reduced cross-sectional area and material usage in products. TPEE has extremely high tensile strength. Compared to polyurethane (TPU), TPEE’s compressive modulus and tensile modulus are significantly higher, enabling TPEE parts to bear greater loads than TPU parts of the same hardness. At room temperature and above, TPEE has a high flexural modulus, yet it remains less rigid than TPU at low temperatures, making it suitable for cantilever or torque-type components, especially for high-temperature applications. TPEE exhibits excellent low-temperature flexibility, with superior notched impact strength atlow temperatures compared to other TPEs, and abrasion resistance comparable to TPU. Under low-strain conditions, TPEE demonstrates outstanding fatigue resistance with minimal hysteresis loss, making it ideal for repeated cyclic loading applications such as gears, rubber rollers, flexible couplings, and belts.

Thermal Properties

TPEE has excellent heat resistance, with higher hardness grades offering better performance. After continuous heating at 110–140°C for 10 hours, TPEE shows negligible weight loss, allowing for very high service temperatures, with even higher short-term use temperatures. It can withstand automotive paint-baking temperatures (150–160°C) and retains mechanical properties well under extreme temperatures. At temperatures above 120°C, TPEE’s tensile strength far exceeds that of TPU. Additionally, TPEE exhibits outstanding low-temperature performance, with a brittle point below −70°C. Lower hardness grades offer better cold resistance, and most TPEE grades can be used long-term at −40°C. Due to its balanced performance at high and low temperatures, TPEE has an exceptionally wide operating range, from −70°C to 200°C.

Chemical Resistance

TPEE has excellent oil resistance and withstands most polar solvents (e.g., acids, bases, amines, and glycol compounds) at room temperature, but it is not resistant to halogenated hydrocarbons (except Freon) and phenols. Chemical resistance improves with increasing hardness. TPEE exhibits good resistance to swelling and permeation by most organic solvents,fuels, and gases, with fuel permeability only 1/300 to 1/3 that of oil-resistant rubbers such as neoprene, chlorosulfonated polyethylene, and nitrile rubber. However, TPEE has poor resistance to hot water, though adding polycarbodiimide stabilizers can significantly improve its hydrolysis resistance. Introducing phenyl-P-naphthyl derivatives (PEN) into thePBT hard segments of TPEE enhances its water and heat resistance.

Weathering and Aging Resistance

TPEE demonstrates excellent chemical stability under conditions such as water mist, ozone, and outdoor atmospheric aging. It can withstand prolonged use without degradation even under high oxygen concentration, intense light, and high humidity. Degradation begins only under strong UV exposure, but incorporating shielding additives like carbon black effectively prevents aging. entration, intense light, and high humidity. Degradation begins only under strong UV exposure, but incorporating shielding additives like carbon black effectively prevents aging.

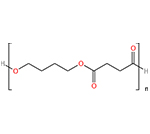

PBT (polybutylene terephthalate) is a polyester made by the condensation of terephthalic acid and 1,4-butanediol. It is a crystalline thermoplastic polyester that can maintain good mechanical properties over a wide temperature range, and has excellent heat resistance, chemical resistance, and electrical properties. Its water absorption rate is low, only 0.1%, and it still maintains various physical properties including electrical properties in humid environments. Mainly used in the fields of automobile manufacturing, electronic appliances, fiber optic communication (the basic material for cable sheath materials), civil and industrial textiles (PBT elastic fibers or other single fiber silk products), polymer alloys and blending industries (as the base resin for modified materials and composites), etc.

More information, please contact with:

Li Huimin,Tel: 0576-85580185 ,Phone: 18825832103, Email:lhm@realsunchem.com